Two sustainability challenges faced by industrial bread manufacturers globally are large volumes of returned bread and reliance on single-use plastic bags for packaging.

Two sustainability challenges faced by industrial bread manufacturers globally are large volumes of returned bread and reliance on single-use plastic bags for packaging.

In 2020, the Baking Industry Research Trust set out to explore whether these each of these challenges might offer the solution to the other —by turning returned bread into a viable, bio-based alternative to conventional plastic bags.

Collaboration was essential from the beginning. The Baking Industry Research Trust and Plant & Food Research (PFR) had a history of working together on bread-related research. They partnered to create a project that investigated the feasibility of extracting valuable materials, especially starch, from returned bread.

Scientists from Scion were identified as essential partners for their expertise in biomaterials and advanced manufacturing. They provided early technical guidance and later led the optimisation of converting extracted starch into thermoplastic starch (TPS).

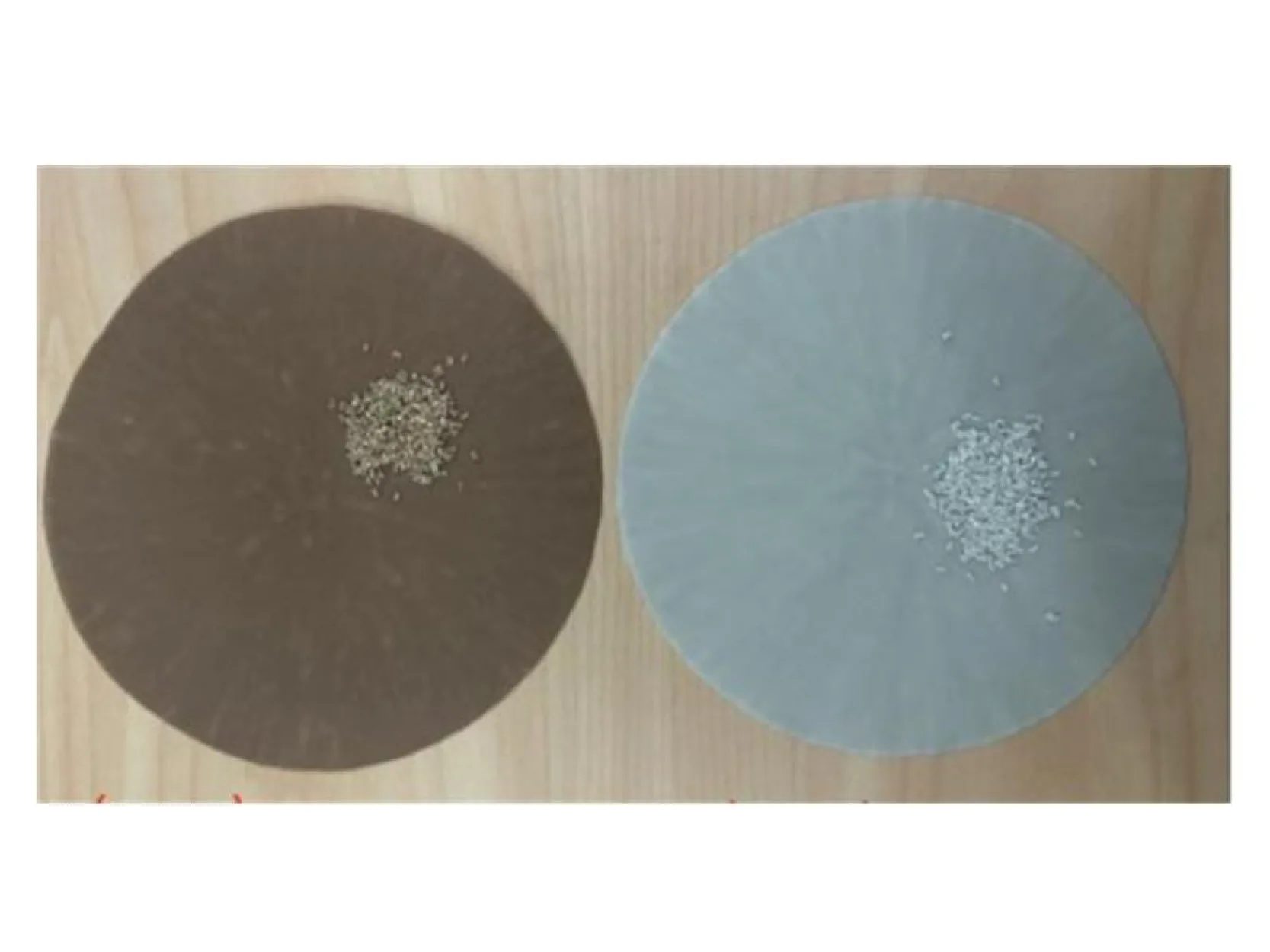

The project unfolded in two major stages. In the initial phase, PFR carried out a review of the intellectual property landscape and performed proof-of-principle starch extraction from returned bread. Researchers supported this phase with technical expertise, helping assess how the extracted starch might behave in downstream processing.

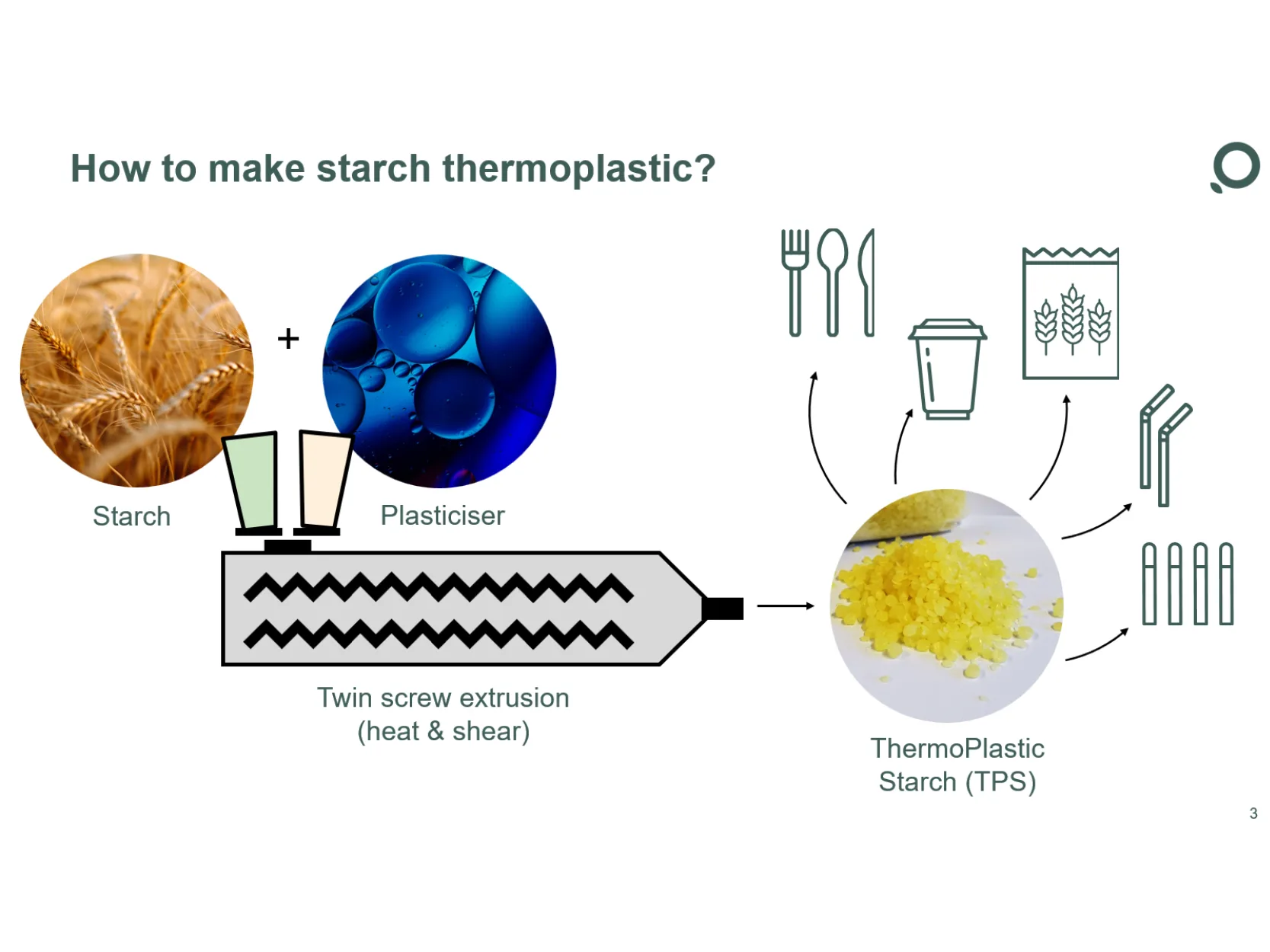

The second stage advanced from laboratory feasibility to materials development. The extracted starch was blended with a plasticiser and processed through extrusion to create thermoplastic starch. This phase included determining the optimal conditions required for plasticisation, blending, and compounding to achieve a workable polymer material. The resulting materials then underwent selected material property tests to benchmark performance and identify potential applications.

A technoeconomic analysis included a full process flow diagram, mass balance, cost estimates for alternative commercial feedstocks, and a preliminary net present value calculation with sensitivity analysis. The results clearly showed that while the production of thermoplastic starch (TPS) from returned bread is technically feasible, it is currently significantly more expensive than the low-density polyethylene used in today’s bread bags. As a result, there are no immediate plans for commercialisation.

Throughout the project, support from the Bioresource Processing Alliance (BPA) played an important role.

The BPA not only provided funding but also worked closely with the Baking Industry Research Trust during the application process, helping refine the project proposal and strengthen its strategic focus. Their backing enabled the research team to thoroughly investigate this complex sustainability challenge.

While commercialisation is not imminent, the project represents a significant scientific and environmental milestone. It demonstrates a circular-economy pathway in which bread waste can be transformed into a functional biomaterial and establishes the technical foundation for future innovations as processing costs decrease and demand for sustainable packaging grows. The Baking Institute Research Trust remains committed to advancing research that reduces waste, supports manufacturers, and promotes a more sustainable baking industry.

Tania is one of the keynote speakers at our forthcoming Sustainable Solutions Symposium. For more information, registration and ticket sales, see the symposium website: https://bpa-sss.co.nz/

You can read more about the Baking Institute Research Trust and their journey here: https://www.bakeinfo.co.nz/

Comments are closed.